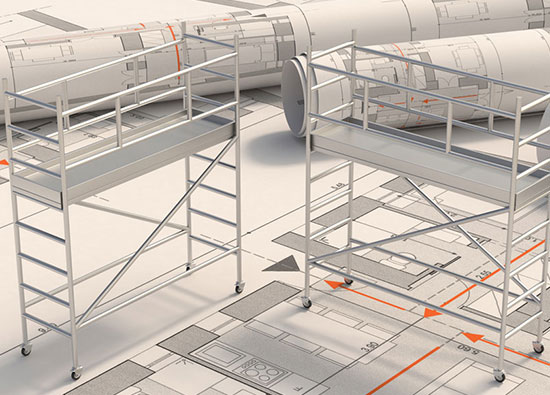

TECHNICAL GUIDE TO CHOOSING THE RIGHT SCAFFOLD

How to choose the scaffolding based on the material, the type of use and the various classes of capacity, height and access.

ADVANTAGES OF USING THE SCAFFOLD

- quick assembly;

- flexibility of use due to mobility;

- versatility linked to possibility. to be quickly reconfigured;

- own stability;

- small footprint;

- ease of transport;

- low weight;

- safety due to the presence of collective protection in all phases of work.

DISADVANTAGES IN USING THE SCAFFOLD

- risks associated with moving;

- risk of overturning;

- encumbrance of stabilizers and stabilizer frames;

- difficult to use on strongly inclined surfaces;

- difficult to use on less compact soils;

- difficult to use in works at high heights;

- limited horizontal efforts that the worker can make when for example using a drill;

- it is impossible to install maintenance or lifting equipment on the scaffolding.

SELECTION CRITERIA

The choice of the suitable scaffolding for carrying out a specific activity depends on the characteristics of the site (space available in height, space available on the plan), the working height and atmospheric conditions, in particular the wind. The employer will choose the model and configuration of the scaffolding most suitable for the nature of the work to be performed, with particular regard to the height of the work platform in relation to the working height and the overall dimensions on the ground, ensuring its stability through the systems provided. by the manufacturer.

The factors to consider for the correct choice are:

The factors to consider for the correct choice are:

- nature of the work to be carried out (duration, quota, repetition, etc.);

- site features such as:

1. dimensions;

2. slope;

3. accessibility (presence of stairs, passage sizes, ease of movement, etc.).

2. slope;

3. accessibility (presence of stairs, passage sizes, ease of movement, etc.).

- dimensions, constraints and protrusions in plan and in height (for example the presence of overhead power lines);

- use of the scaffolding in the presence (external use) and / or in the absence of wind (internal use);

- height of the work platform in relation to the working height;

- overall dimensions of the scaffold including that of stabilizers, stabilizer frames and / or ballasts;

- suitability of the structure on which to anchor the scaffolding in the cases provided for by the manufacturer.

TO CHOOSE A SCAFFOLD YOU MUST ALSO TAKE INTO ACCOUNT OF THE CLASSES

- load classes

- usage classes

- height classes

- access classes

IN CONCLUSION

There are various types of scaffolding on the market, each one designed specifically to meet the needs of workers and concretely facilitate the operations requested by the client. Svelt, has specialized since 1964 in the production and sale of scaffolding (we can also boast the invention of the first "modern" scaffolding in Italy in 1964.

The first major differentiation in the field of scaffolding takes into consideration the type of work to be carried out with the aid of the tool.

Specifically, there are solutions for:

The first major differentiation in the field of scaffolding takes into consideration the type of work to be carried out with the aid of the tool.

Specifically, there are solutions for:

- domestic use

- professional use

THE MATERIAL OF SCAFFOLDS

The materials used for the construction of the scaffolding are two:

- aluminum

- steel.

- More rarely, insulating fiberglass is used but only for specific jobs in the presence of high voltage.

Steel scaffolding: those who choose it want a more suitable product to withstand stress and stresses of various kinds, especially in the construction sector. A traditional product in electrolytically galvanized steel that has a resistance, a duration and a weight on average higher than those of aluminum and, for the same type, a lower cost. The number of pieces composing it is considerably higher than the aluminum models and the assembly system requires more time and normally the presence of 2 operators.

Aluminum scaffolding: those who choose it want a lighter and faster product to assemble and to use especially for installations where assembly time is precious compared to that of the intervention. Limited weight and great manageability for a sturdy product but which certainly requires attention and care in use higher than those necessary to keep a steel scaffolding in good condition. Stress resistance and weight are lower than those of steel, and (for the same type) the cost is higher. The number of pieces that composes it is considerably lower than the steel models, and the assembly system is almost always quick to assemble with automatic hooks and fusions that make use extremely comfortable. Given the lightness, many aluminum scaffolding are multi-position and have automatic openings with pre-assembled bases that open and close in a few seconds. Several models can be assembled by a single operator. Those who choose an aluminum scaffolding can benefit from a more delicate but also light and extremely handy tool in transport that takes up less space both in the van and in the warehouse. The wheels are also often equipped with telescopic legs that allow use even on sloping or stepped ground. The aluminum scaffolding can also be equipped with overhangs and extensions, to work in more complex situations.

For over 55 years, we at Svelt, a company from Bagnatica in the province of Bergamo, have been dealing with the production of quality scaffolding made on the basis of maximum safety, a concept that has always been the basis of our company philosophy and that we carry forward through a continuous and scrupulous research and innovation.

Contact us by email at export@svelt.it or call +39 035 681663 for more information or to receive a quote, we will be happy to help and advise you on the right and safest choice based on your needs.